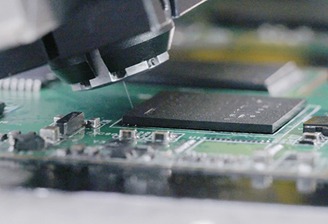

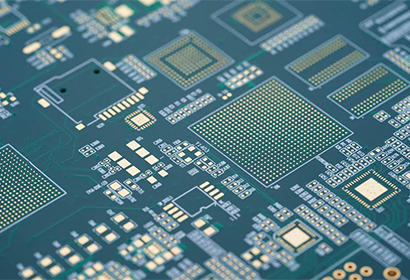

With the growing reliance on electronic devices and their rapid refresh cycles, axxon delivers precision SMT PCB assembly solutions that meet escalating quality demands and rigorous physical specifications for modern electronics.

Key Industry Requirements:

✓ PCB SMT assembly processes for both rigid/flexible boards

✓ axxon-enhanced encapsulation/underfill/adhesive operations

✓ Mission-critical precision for mobile device sealing (dust/waterproof)

axxon Technology Advantages:

3D laser-guided SMT assembly equipment ensures:

• 100% process yield rates

• Real-time dispensing path tracking

• Perfect glue pattern formation

axxon continues to innovate with market-driven PCB SMT assembly technologies, earning industry recognition through customized solutions that maximize production efficiency and product reliability for global partners.

Underfill

Underfill plays a critical role in enhancing the protection of electronic components, effectively improving resistance to thermal stress, vibration, and shock.

Electronic Components / Pin Encapsulation

axxon's SMT assembly equipment ensures precise PCB SMT assembly of electronic components with high reliability and miniaturization capabilities.

SMA

SMT red glue is a single-component epoxy resin adhesive stored at room temperature, which rapidly solidifies upon heating.

Corner Bonding

Reinforcing the bonding strength of large components such as BGAs or CSPs (Chip Scale Packages) is essential.

Chip Cooling

Excessive heat generated by high speed chips must be transferred heat sinks via thermal interface materials.

Solder Paste in SMT Industry

Solder paste is a critical material in Surface Mount Technology (SMT), widely used for soldering electronic components like surface-mount resistors, capacitors, and ICs onto printed circuit boards (PCBs). As a modern soldering solution, it consists of a homogeneous mixture of solder powder, flux, surfactants, and rheology modifiers, ensuring reliable electrical and mechanical connections.

Plasma Cleaning

PCB's and products are not always clean when they arrive to the production floor. Surface contaminants such as oxides or other contaminatns may be present that can reduce the adhesion or wetting of fluids. Surface treatment technology can eliminate these contaminants.