Solder paste is a critical material in Surface Mount Technology (SMT), widely used for soldering electronic components like surface-mount resistors, capacitors, and ICs onto printed circuit boards (PCBs). As a modern soldering solution, it consists of a homogeneous mixture of solder powder, flux, surfactants, and rheology modifiers, ensuring reliable electrical and mechanical connections.

Key Features & Applications of Solder Paste

Primary Use: Bonding SMT components (resistors, capacitors, ICs) onto PCBs.

Composition:

Solder powder (main conductive element)

Flux (cleans surfaces, prevents oxidation)

Additives (surfactants, rheology modifiers for stability & printability)

Application Methods:

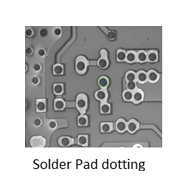

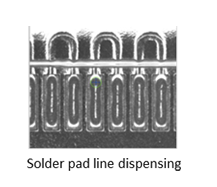

Solder paste printing (stencil printing): Most common method for high-volume production.

Dispensing solder paste (single-point deposition): Ideal for fine-pitch components, 3D geometries, and mixed-technology PCBs.

Advanced Solutions:

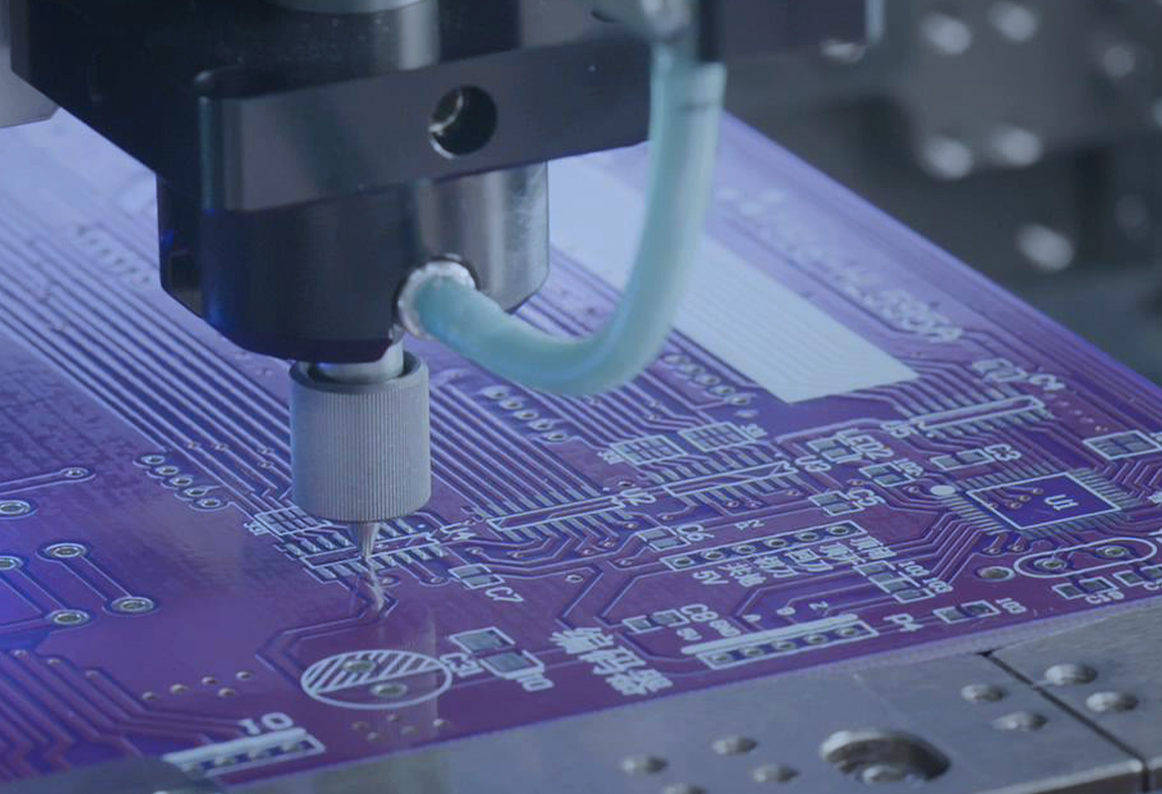

Solder paste dispenser: Enables precise deposition for complex assemblies.

Electric solder paste dispenser: Automated systems for high-accuracy dispensing.

SMT solder paste dispenser: Optimized for surface-mount technology requirements.

With the trend toward miniaturization and complex PCB designs, solder paste dispensing is becoming increasingly important alongside traditional solder paste printing. Innovations like SMT solder paste dispensers ensure efficient and reliable soldering for modern electronics manufacturing.

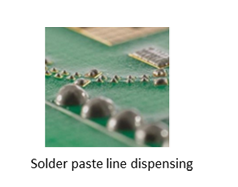

Solder paste dispensing is a critical process in SMT assembly, enabling precise deposition for high-density and mixed-technology PCBs. Various dispensing methods, including jetting, auger valve, and time pressure, offer flexibility for different applications, ensuring reliable solder paste application even on complex geometries.

Key Solder Paste Dispensing Methods

Time Pressure Dispensing

·Mechanism: Uses compressed air pulses (and sometimes vacuum) to push solder paste from a syringe through a dispense needle.

·Advantages: Simple setup, cost-effective for low-to-medium volume production.

·Limitations: Less precise than auger or jetting; sensitive to material viscosity changes.

Jetting Technology (Non-Contact)

·Mechanism: Ejects solder paste droplets onto the substrate without physical contact.

·Performance: Capable of ~0.5mm dot diameters (e.g., Mycronic’s solder jetting technology).

·Benefits: High speed, minimal clogging, ideal for fine-pitch components.

Auger Valve Dispensing (High Precision)

·Mechanism: Uses a rotating auger screw to precisely meter and dispense solder paste.

·Control Parameters: Adjustable speed, acceleration, forward/reverse motion.

·Precision: Achieves ultra-fine deposits (e.g., axxon V-8000 series: ~0.15mm dots, ~0.2mm lines).

Critical Factors for Consistent Solder Paste Dispensing

·Dispense Tips: Customizable in geometry (tapered/straight), length, diameter, and material.

·Dispensing Height: Critical for repeatability; automated calibration ensures accuracy.

·Surface Detection: Laser height sensing ensures proper alignment before dispensing.

·Automation: Electric solder paste dispensers (e.g., SMT solder paste dispensers) enhance process stability.

With advancements in solder paste dispensing technology, manufacturers can achieve higher precision and efficiency, making it indispensable for modern PCB assembly alongside traditional solder paste printing.