The dispensing process enables the camera module to be more compact while maintaining superior image quality.

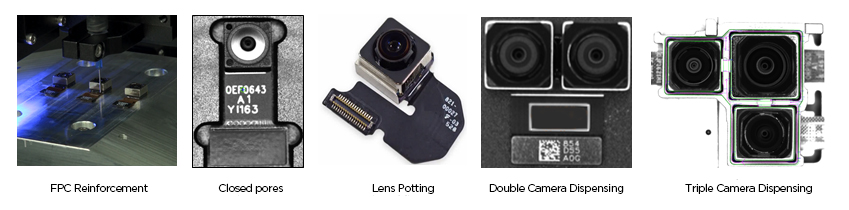

The dispensing process is an essential component of the camera manufacturing process. It is employed in a multitude of applications within the camera module production cycle, including the bonding of components, lens fixation, the reinforcement of soft boards, the solder protection of motor pin feet, the fixation of dual and triple camera brackets, and the sealing and waterproofing of modules.

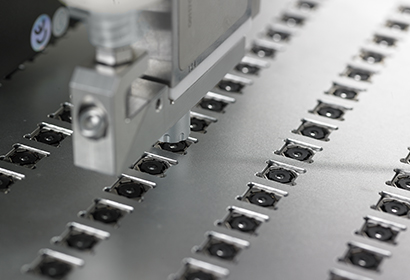

As society progresses, there is an increasing demand for higher image quality from CCM cameras. This has led to a corresponding increase in the size of the sensitive chip and lens, while the volume of the module remains relatively fixed. Consequently, there is less space available for dispensing, which in turn has resulted in more accurate dispensing systems. Module factories operate on a mass production basis, with shipments calculated in KK. In this context, dispensing efficiency is of critical importance.

Axxon has consistently demonstrated a commitment to technological advancement and innovation. In terms of hardware, the dispensing method has evolved from traditional needle dispensing and pneumatic jetting valves to the piezoelectric valve, which offers enhanced efficiency and a smaller point diameter. Our software solutions feature a robust visual algorithm library, enabling precise and rapid positioning of products of varying shapes and materials.