The Axxon Mycronic APJ1500 piezo jetting valve offers the capability to precisely dispense a wide range of materials.

The APJ1500 is widely used in the SMT, FPC, LED, PCB and semicnductor industries. The range of applications span energy, life sciences, optics, MEMS, RFID, and many others where high precision, high consistency, high efficiency and non-contact processing are required to deliver reliable electronics products.

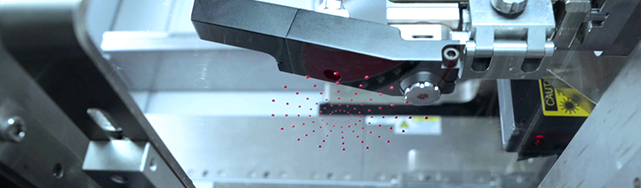

- High speed jetting: No Z Axis motion, jetting speed up to 1000 dots per second, 3 to 7 times faster than traditional jetting technologies

- High precision: Minimum dot size is 0.2mm and unmatched consistency

- High flexibility: Non-contact jetting to avoid collision with components, minimum droplet of 1nl for tight spaces

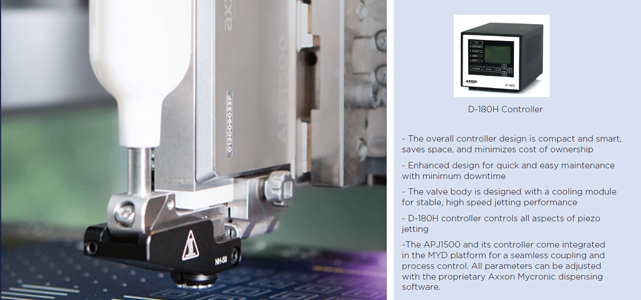

- Minimal maintenance and long life: Quick release design for easy maintenance and minimized downtime, wear resistant materials for 20 times longer lifetime

- Unique structural design: Strong jetting force within short stroke reduces bubbles and splashes, temperature control for valve body and fluid channel for ultimate jetting consistency

- Patented design

· Underfill · Dam and Fill · Hot Melt · Pin Encapsulation · Precision Coating · Corner / Edge Bonding

wide viscosity range up to 200,000cps

Technical Data | APJ1500 |

Maximum frequency | 0~1000Hz |

Maximum fluid pressure | 0~0.3MPa |

Minimum dot diameter | 0.2mm (for specific epoxies, smaller dot sizes can be achieved, down to 0.14 mm) |

Applicable fluid viscosity | 1~200,000cps |

Dimension | 117x25.4x76mm |

Weight | 440 g |

Maximum nozzle heating temperature | 200℃ |

The APJ1500 piezoelectric valve can be integrated with any precision dispensing system.