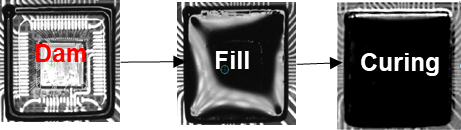

Dam & fill is used in the encapsulation of semiconductor chips and components to provide reinforcement, seismic resistance, and protection against dust and water ingress.

With the continuous development of consumer electronics products, Dam & fill has become an essential process for enhancing the lifespan and quality of electronic devices. In the Dam & fill process, a dual-valve system is typically employed, where one valve is responsible for forming the dam using a high-viscosity adhesive, while the other valve is used for filling with a low-viscosity adhesive. This technique is commonly applied in semiconductor packaging, wire bonding encapsulation, smart card chip packaging, and TP screen bonding processes. Dam & fill effectively encapsulates the die or chip, thereby safeguarding semiconductor components and prolonging their operational lifespan.

Dam & fill is widely utilized in processes such as semiconductor packaging, wire bonding encapsulation, smart card chip packaging, and TP screen bonding.

In the Dam & fill dispensing process, precise control of adhesive volume, dispensing path, and dispensing speed are essential for ensuring uniform coverage of Dam height and Fill adhesive, with no scattered points or air bubbles.

With the rapid development of the electronics industry, there are increasing demands for aesthetics, waterproofing, and impact resistance in electronic products. Particularly in Dam & fill processes, there are higher requirements for the final dispensing thickness, which typically features a 'flat top' shape. This inevitably raises the demands on dispensing systems for accuracy in adhesive volume, dispensing stability, and overflow width.

Axxon's non-contact jetting dispensing system combined with contact dispensing systems is an ideal choice for achieving Dam & fill applications, enabling precise dispensing in targeted areas. Additionally, Axxon has independently developed core products such as jetting valves and piezo valves, providing mature and reliable solutions. In response to future demands, Axxon has increased its investment in research and development, achieving significant breakthroughs in high-precision dispensing, precise control of adhesive width and height, and dispensing efficiency.

Dispensing performance