Integrating technology into functions such as cameras, entertainment, and information dissemination makes waterproofing and shock resistance crucial.

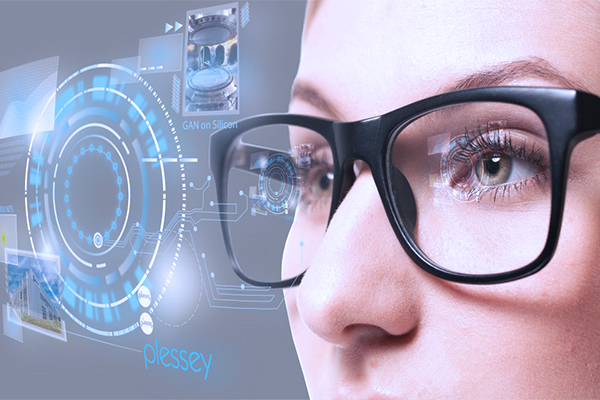

Smart glasses/AR/VR/MR glasses requires protection against sweat and rain to prevent damaging, external moisture from entering the internal circuitry through the arms of the glasses. This protection is achieved through the use of adhesive bonding. The functions of adhesive bonding include adhesion, filling, sealing, shock absorption, and heat dissipation.

The main components of adhesive bonding in glasses include: underfilling the main chip of the circuit board, encapsulating the battery protection board, using thermal conductive silicone grease for heat dissipation, adhesive bonding and sealing the outer shell, and sealing solder joints, among other fluid dispensing processes.

The internal design of glasses arms needs to consider heat dissipation, interference, sound quality, battery life, weight, fixation, connection, etc. Due to the numerous components and limited space, some parts may be difficult to bond. Additionally, since most glasses arms are made of plastic, deformation may occur, leading to problems such as off-center bonding, adhesive overflow, and insufficient adhesive.

To enable adhesive bonding from multiple angles, a multi-axis motion control system is required, along with multi-channel visual recognition lighting. This is achieved through complex, visual edge detection and laser height sensing to prepare the adhesive bonding trajectory.