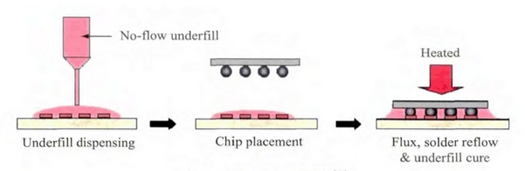

No-flow underfill adhesive serves as a flux during the early stages of chip packaging, transitioning into an adhesive for under filling during reflow soldering.

With the continuous development of consumer electronic products, the size of packages is gradually shrinking, making under filling an essential process for enhancing the reliability of electronic products. No-flow underfill simplifies the process flow by eliminating the need for capillary action of the adhesive. The under filling is performed before solder ball attachment, and during the reflow soldering process, both solder ball attachment and underfill curing are completed simultaneously. This protects semiconductor components and enhances their lifespan.

The no-flow underfill is widely employed in the packaging process of flip-chip devices.

During the dispensing process of no-flow underfill, precise control over adhesive volume, dispensing path, and valve parameters is crucial to ensure the integrity of dispensing coverage, absence of air bubbles, and dispensing thickness.

With the advancement of the microelectronics industry towards lightweight, thin, small-sized devices, along with an increase in I/O counts and functional diversity, there arises a growing demand for simplified process flows and higher precision in dispensing systems, including accurate dispensing volume control and stable dispensing. Therefore, the emergence of no-flow underfill technology addresses these requirements.

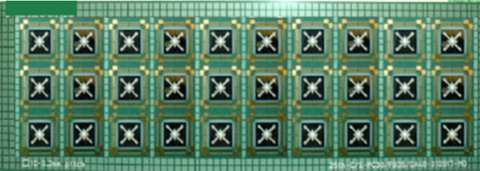

Axxon's non-contact jet dispensing systems and contact dispensing systems both offer precise control over adispensing volume. Furthermore, Axxon is committed to researching the no-flow underfill process and has accumulated extensive experience in this field. Additionally, Axxon possesses mature and stable high-speed, high-precision motion platforms, which can be flexibly combined with independently developed dispensing valves to meet various dispensing needs for different products and adhesives.