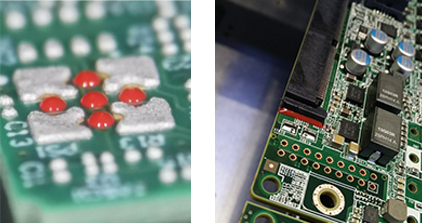

Surface Mount Adhesive is a single-component epoxy resin adhesive stored at room temperature, which rapidly solidifies upon heating.

The fluid properties of Surface Mount Adhesive (SMA) allow it to be dispensed at high rates of speed. It maintains a uniform profile without tailing, overflowing, or slumping. Its viscosity characteristics, known as 'shear thinning,' and low moisture absorption make it suitable for jetting and auger valve dispensing. Properties from various suppliers will differ giving you the opportuity to select characteristics such as storage, profile, shock resistance, CTE, color, etc.

The primary function of SMA is to enhance the adhesion of components, preventing displacement or detachment during the reflow process, and ensuring the stability of large components. It is predominantly used in SMT (Surface Mount Technology) assembly and wave soldering processes, with applications spanning industries such as consumer electronics (e.g., smartphones, watches), household appliances, automotive electronics, and others.

In the process of SMA dispensing, key process parameters to consider include volumetric repeatability, jetting force, dot placement accuracy, speed, and smallest shot size. Selecting dispensing technology with high Dots Per Hour (DPH) will ensure the most value from yoru system.

The increasing integration density of PCBs results in reduced dispensing space and an increased number of dispensing locations. Consequently, the industry trend in SMA gravitates towards achieving smaller, single-point dispensing and enhancing equipment speed through higher acceleration specifciations. This trend emphasizes smaller single-point dispensing with quicka nd accurate short distance moves.

With years of experience in SMA, Axxon Mycronic has developed mature and reliable jetting technology and motion platforms. In response to future demands, R&D investement continues with emphasis on smaller shot sizes, reliable and faster pump technology faster gantry positioning.

Dispensing performance