1K progressive cavity pump

Axxon V-9000 progressive cavity pump is a continuously volumetric dispense pump.

Utilizing a precision manufactured rotor and stator results in outstanding repeatability and long term use over a wide range of fluids. The DC motor controls forward and reverse motion of the rotor for controlled dosing and suck back. Progressive Cavity technology is the highest level of precision for all industries.

Features and advantages

• Long term stability and repeatability

• Volumetric reverse for a clean dispense and no drooling

• Flow rate is easily adjusted to meet process requirements

• Precision dosing control for uniform geometry of a continuous bead or area fill

• Sealed system does not drip, even with low viscosity fluids at high pressure

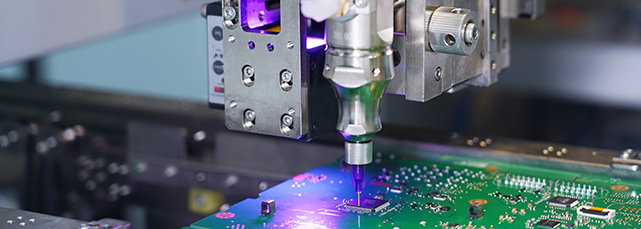

Application

• Optical communication industry

• BGA component packaging

• LCD, LED component assembly

• PCB surface electronic component soldering

• Camera, voice coil and sensor module packaging

• Bead dispensing, sealing, casting sealing and other micro-dispensing

Compatible fluids

• Methyl methacrylate • Acrylic ester • UV adhesive • Adhesives

• Sealants • Cosmetics & Pharmaceutical

Specification | V-9000 |

Viscosity range | 1~1,000,000cps |

Max. rotation speed | 120r/min |

Min. dot diameter | 0.15 mm |

Max. fluid pressure | 2MPa |

Operating environmental pressure | 0~0.6MPa |

Max. volume flow | 60mL/min |

Main chamber material | Aluminum alloy |

Material of drive section | Stainless Steel & Aluminum Alloy |

Stator material | Chemical And Abrasion Resistant Rubber |

Rotor material | Ceramic & Metal & Rubber |

Sealing component | FFKM & PTFE & UPE Variseal |

Feeding mode | Cylinder feeding/Tank feeding |

Mounts | Dovetail groove type |