LED technology has gradually entered the public's daily life, and LED products have become widely used in various industries, including

- Matrix LED automotive lights, which provide greater brightness and can better identify pedestrians and obstacles. In addition, they can selectively illuminate based on road conditions and automatically dim when oncoming vehicles are approaching at night to improve driver safety.

- LED lighting used in streetlights and indoor lighting saves at least 100 billion kilowatt hours annually nationwide, equivalent to the consumption of 500 million tons of coal, reducing carbon dioxide emissions, promoting energy conservation, environmental protection, and protecting the planet.

- LED products are closely related to various applications such as televisions, backdrops, outdoor billboards, indoor decorations, and stages, presenting vivid and colorful images, creating a pleasant visual lighting effect, and gradually entering ordinary households.

- City light shows transform urban landscapes into spectacular displays, especially at night, where mesmerizing scenes illuminate the skyline, showcasing the unique features of each city and highlighting China's technological prowess.

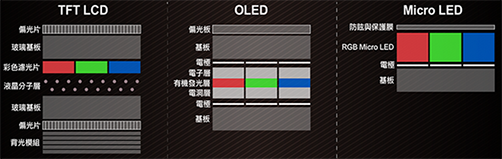

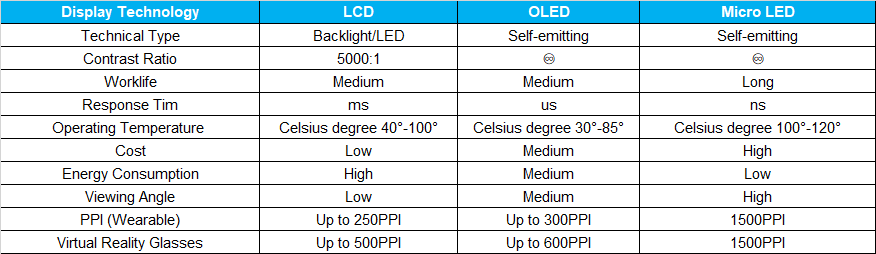

Future LED development trends include the evolution of LED to OLED, mini LED and micro LED technologies.

- From the perspective of energy conservation and environmental protection, the goal is to maximize the conversion of electrical energy into light energy, thereby reducing energy consumption and promoting environmental friendliness.

- From a color display perspective, the goal is to achieve finer color resolution, more vibrant colors, and more lifelike image reproduction.

- For LED form factor products, the focus is on moving away from conventional rectangular shapes. Diversification and customization are the demands of the changing times.

- Resolution: With more LEDs per unit area, display resolution will increase, placing greater demands on packaging technology.

- Diversification: Seamless splicing will be achievable, allowing shapes to be tailored to specific requirements without the need for extensive custom designs.

- Level of protection: Factors such as waterproofing, dustproofing, solder joint protection, oxidation prevention, heat dissipation, vibration resistance, temperature and humidity tolerance, and others will play a role.

Axxon is actively working with LED back-end assembly plants to prepare for future technology changes and to research products that will adapt to these changes.